02 Aug What’s Working: JSU Engineering Students create temperature mats for diabetics By Andrew Harrison

JACKSON, Miss. (WJTV) — We’ve all seen the numbers. Mississippi has some of the highest diabetes rates in America. A diagnosis can be devastating. Sometimes patients eventually have to have their feet removed. A team of aspiring engineers at Jackson State is working to prevent amputations.

Inspiration meets innovation in effort to keep diabetics everywhere walking tall.

It began as an engineering class project 17 months ago.

Chevan Baker is a senior engineering student at Jackson State University.

He remembers, “At times, when we had very strenuous work to do, we kind of just balanced each other out. It seemed like it wasn’t work. It was fun.”

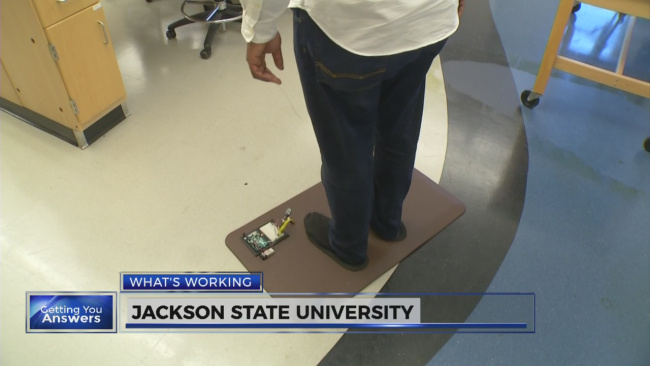

These engineering students at Jackson State have created mats, diabetics can step on to have the temperature taken on the bottoms of their feet.

Jordan Barber is a team member and recent graduate of JSU.

He explains, ” Patients who keep track of their feet temperature have a better chance of catching their foot ulcers earlier.”

Left untreated foot ulcers can lead to amputations.

JSU Grad Student Jann Butler explains, “Every one of the team members had a close friend or relative that has been effected by diabetes.” Similar products are out there, but these students believe several factors set their creation apart.

According to Jordan Barber, ” The mat is important because it takes the temperature, but also our app because it allows them to communicate that information with their doctor.”

There are still a few kinks to iron out in the app, but the team has already applied for a provisional application patent.

Chevan concludes, ” It’s refreshing to go out there and be this young, and kind of be an advocate at a young age and show that we can do it and so can other young individuals.”

The mats can be used on most surfaces, and they are water proof so moist feet won’t give you an inaccurate reading. I am Andrew Harrison, and that’s, “What’s Working” in Mississippi this week.

We’ll be sure to let you know when the product is officially ready for market. Right now each unit costs about $500 to produce.

Sorry, the comment form is closed at this time.