04 May In Tanzania, This Startup Will Pay For Plastic Trash And Make 3-D Printer Filament

It’s hard to make a living as a waste picker. In Dar es Salaam, Tanzania—where most trash ends up illegally dumped—waste pickers spend up to 12 hours a day walking around the city, collecting and lugging other people’s garbage in long plastic bags. It’s a valuable service for the city, which doesn’t have a recycling program. But it doesn’t pay very well. In a day, a full-time waste picker might make less than $1.50.

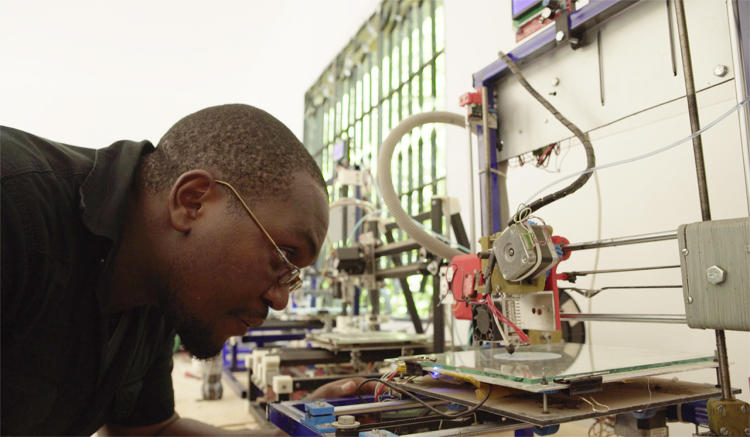

A new startup plans to help waste pickers earn more by turning plastic waste into a more valuable product: 3-D printing filament, the plastic thread-like material that 3-D printers use instead of ink. Recycling plastic bottles into filament can help waste pickers increase their incomes by as much as 20 times.

The startup will launch in Dar es Salaam and plans to expand to other cities. Around the world, around 40 million waste pickers currently earn less than $2 a day for their work.

It’s hard to make a living as a waste picker. In Dar es Salaam, Tanzania—where most trash ends up illegally dumped—waste pickers spend up to 12 hours a day walking around the city, collecting and lugging other people’s garbage in long plastic bags. It’s a valuable service for the city, which doesn’t have a recycling program. But it doesn’t pay very well. In a day, a full-time waste picker might make less than $1.50.

A new startup plans to help waste pickers earn more by turning plastic waste into a more valuable product: 3-D printing filament, the plastic thread-like material that 3-D printers use instead of ink. Recycling plastic bottles into filament can help waste pickers increase their incomes by as much as 20 times.

The startup will launch in Dar es Salaam and plans to expand to other cities. Around the world, around 40 million waste pickers currently earn less than $2 a day for their work.

“This is born out of my experience working with social enterprises in Nairobi, Kenya—just seeing waste collectors, how they live, what they have to do for the plastic, and how they struggle to support their families,” says Jasper Middendorp, founder of Reflow, the Amsterdam-based startup making the new recycled filament. “It started from seeing what are the ways we could help waste collectors improve their lives, and what are the high value products we could make.”

They learned about Tech for Trade, a U.K.-based nonprofit that has developed open-source technology to recycle plastic into 3-D printer filament, and decided to partner with them to create a social enterprise.

“I just saw the huge disparity between what some of the poorest people get for the plastic, which is around seven cents a kilogram, to what filament costs, which is $25 a kilogram,” he says. Making filament is a way to get much more value from the plastic than other recycled plastic products, while only using a small amount of material; 120 plastic bottles can produce a kilogram of filament.

Demand for the filament is growing: one forecast suggests that 3-D printer sales will double each year for the next few years. By 2019, 5.6 million 3-D printers will sell in a year.

Reflow plans to work directly with waste pickers to collect plastic, clean and shred it, and use a low-cost extruder to turn it into a finished product. The quality, they say, will be the same as what someone can buy on the market now.

The company is working on various models to pay waste pickers. “The value increase for them is around 20 times what they make now from the plastic they sell, but that’s not the best way to go about impact—giving one waste picker 20 times as much as he makes now,” says Middendorp. “So we’re looking into finding ways to either prolong the impact—give them a sustained level of income—or spread it out over a larger group.”

They also plan to invest in local manufacturing resources, like 3-D printing and CNC milling, to support the growth of the local economy.

As they choose cities to work with, they hope to locate near their biggest markets. For North America, for example, they may work in Mexico. While the technology could also be used to recycle plastic bottles in New York City or San Francisco, Reflow believes the biggest impact of the program is helping the lowest-income waste pickers—not just recycling plastic.

The company thinks that developing countries will eventually also become bigger markets for the product, 3-D printing objects that are currently shipped in from elsewhere. “We think the technology can actually mature in these countries,” says Middendorp. “A lot of the problems the technology solves around distribution and transport are bigger there.”

Reflow is running a crowdfunding campaign on Kickstarter.

Sorry, the comment form is closed at this time.